Inside the Spark: Continuously Variable Transmission: It's All About the Fluid

This post originally appeared on Reddit.

TL; DR

-

Both Gen 1 2014-2015 and Gen 2 2016+ Chevy Spark models have a variant of Jatco JF015E.

-

Originally 2014 Sparks came with transmission software that was always shifting to the low gear, causing shocks, resulting in premature belt and pulley metal wear. An update was issued for CVT firmware to prefer staying in high gear on deceleration (PI1309). 2015+ Sparks are coming with this update preinstalled. This is now a normal behavior and can't be changed.

-

CVTs on all 2014+ Spark models are not sealed. They are serviceable and you should perform the maintenance at least every 45K miles unless you drive on the highway all the time.

-

CVT performance is heavily influenced by the state of the fluid inside. Deteriorated fluid will cause the belt to slip producing shudder. No, this shudder won’t disappear on its own, it will only get worse.

-

Shudder is different from slow smooth acceleration, which is a feature of this transmission.

-

Fluid is not the only thing that can go wrong, so contact your dealer if you have transmission concerns. If you are driving a 2014 model and did not get the CVT TCM update at the dealer, the chances of transmission damage increase, so there is a campaign for 2014-2015 model year vehicles to replace damaged transmissions.

Background

The main task of transmission is to adapt the output of the engine to the drive wheels. In order to provide more torque to the wheels, transmission makes the output rotate slower resulting in more torque. If you need higher speed, transmission makes the output rotate faster with reduced torque. Transmission also deals with the reverse gear because engines always rotate in one direction.

Starting from 2014, Chevrolet ships Sparks with three kinds of transmissions:

-

A manual one where the operator has full control over the timing of switching the gears, effectively changing the ratio of the wheel to engine rotations.

-

A Continuously Variable Transmission, where the gears are replaced with a system of a push belt and pulleys, this post is about the CVT.

Side note: In 2016 Opel Karl also gained AMT - Automated Manual Transmission called Easytronic 3.0 in European and South Korean markets - https://www.carscoops.com/2016/03/opel-adds-affordable-easytronic-30/.

Imagine a bicycle with multiple gears. Your gear at the rear wheel allows you to change how much of your input goes towards the torque vs the speed. If you want to start moving or go uphill, you will want more torque, which will be the smallest gear, and you will pedal faster. If you are on a flat surface, you need more speed, so you pick the largest gear and do not need to put much power into the pedals. Fancier bicycles have gears on the input shaft (where pedals are attached) too, which allow finer control over torque vs speed.

Now, replace the fancy gears with pulleys and put a flexible steel belt between them instead of a chain, add a 850+ PSI oil pump to supply hydraulic pressure for switching the ratios and engaging the gears, fill it with about 3.2 quarts of CVT fluid to carry the pressure and keep things lubricated, add valves to direct the pressure to the correct channels, add another two speed gearbox with reverse gear, and you’ll have the Jatco JF015E, aka CVT7.

Jatco CVT7 transmissions are installed in subcompact cars, for example:

-

Chevrolet Spark – 1.0L (75hp), 1.2L (84hp), 1.4L (98hp)

-

Mitsubishi Mirage 1.2L (78hp)

-

Multiple Nissans – Cube 1.8L (122hp), Juke 1.6L (188hp), Note 1.6L (109hp), etc.

-

Others - see list at https://en.wikipedia.org/wiki/List_of_Jatco_transmissions and https://www.marklines.com/en/report_all/wsw0012_201408.

Since CVT allows matching engine output to wheels without driver's interaction, it allows running the engine at the most efficient RPM for every speed, resulting in good fuel economy. This, and smaller package are the reasons for using CVT7.

Side note: Bicycles can have CVTs now as well, see https://www.evelo.com/evelo-difference/nuvinci-n360-drivetrain/.

Operation

CVT7 has an auxiliary two-speed gearbox attached to the output shaft, which allows switching between low, high and reverse gears. Low gear is used to increase torque at slow speed, while the high gear is used at 27 mph (43.4 km/h) and above (per https://gearsmagazine.com/magazine/the-jatco-cvt-power-glide). Transmission belt always rotates in the same direction.

Once the car has accelerated to 8-18 mph, another optimization kicks in, that locks up the torque converter, and connects the engine to the transmission without going through the fluid coupling. On deceleration, torque converter is unlocked from the engine. TSB describing CVT behavior to the dealers says those changes can be perceived as shifts.

Due to drivers complaining that the CVT does not sound like a regular automatic transmission, Transmission Control Module has code for simulating shift steps on rapid acceleration and this cannot be changed.

The only setting that physically changes the configuration based on driver’s input is the “Park”, where a piece of metal physically blocks the output shaft.

Fluid!

CVT7 operation depends on the availability and quality of the transmission fluid (GM 19260800 in US at the time of writing). It is used to send pressure from the valve body to the clutches and pulleys, transfer power between the engine and transmission in the torque converter, lubricate and cool the internals.

Transmission warms up much slower than the engine, 2nd gear upshift is not enabled until transmission warms up to –20C (4F), and torque converter lockup is not enabled until transmission reaches 20C (69F), so starting the car in the winter and flooring it immediately will not work as expected. You can use Torque Pro with an OBD-II reader to get the transmission temperature reading.

Per PI1247A TSB, operating temperature range is 50-80C (122-176F), and the power will be reduced if transmission becomes too hot as that will lead to deteriorated fluid quality. There is a cooling loop that attaches to the main radiator to keep the transmission fluid within the operating temperature, though I have seen it go 5C above that on a hilly road.

It is unlikely that you will be low on fluid unless you have a leak, but its condition is important.

Maintenance

User manual lists CVT fluid change only in the “severe” maintenance interval, and most likely your operation of this city car can be considered “severe” with frequent start/stops and operating the car before the transmission warms up.

Deteriorated fluid causes transmission belt slip, which manifests as "shudder" on acceleration. When fluid is bad (due to age, heat, additives going bad, and normal contamination from parts), its lubrication properties change, allowing the belt to slip. This feels like car cannot figure out whether to accelerate or decelerate when you step on the accelerator pedal. Or when you are going uphill and the car suddenly loses and immediately regains acceleration as if you briefly pressed on the brake.

If your car starts manifesting any of these, consult your dealer or a mechanic who has access to GM TSBs and programming tools. You may only need to replace the fluid, which you can also do on your own, but it is time consuming.

In case of damage to the valve body, GM allows replacing that part in 2016+ sparks, but for 2014-2015 models the official repair process is to replace the whole transmission and there is a campaign (thanks, u/glassgypsy for that!). The shudder caused by the belt slip will not go away once it starts. Prolonged driving with this condition may result in total CVT failure and loss of propulsion.

Reliability

2014 Sparks had transmission control unit programmed to always drop to low gear on deceleration, which caused heavily increased wear to the point of shearing metal from the belt and pulleys. This metal will then damage other parts of transmission. Subsequently, a TCM firmware update was designed to prevent shifting into low gear unless the rate of deceleration is sufficiently low. You can see an example of a sheared belt metal and debris in https://youtu.be/wjHHlv-fiWQ?t=284.

The primary issue with this CVT is that the steel belt is "connected" to the pulleys using friction, and will eventually fail to grab the pulleys after both the belt and pulley surfaces wear out.

I could not find good source of reliability numbers for Chevy Spark CVTs. Some CVT7 survive for 170k miles, some fail after 5 years of drivetrain warranty.

There are a few other things that may cause reliability issues in the long run:

-

Increased parts count increases the chance of the failure.

-

The forward gear may fail due to thin sun gear metal thickness (per https://www.transmissiondigest.com/the-problematic-cvt-7/).

-

CVT Fluid replacement is neither listed in the manual for "normal” service interval, nor service centers recommend doing that (and, based on u/sonicboom1992's post, not all even perform this service, even though it is described in ACDelco TDS), ensuring that drivers will have deteriorated performance that may lead to damage in the long run.

-

High oil pressure (at least 850 PSI - https://gearsmagazine.com/magazine/jf015e-common-issues/) required to control various parts requires a heavy-duty oil pump and it was a source of problems for other CVT7-based vehicles when the oil pump flow control valve fails to maintain required pressure due to wear caused by contaminated fluid.

-

CVT fluid is cooled through the main radiator, so if the loop within the radiator develops a leak, the CVT will be starved of fluid.

Is the 2016+ Gen 2 transmission better than 2014-2015 Gen 1?

Unfortunately, there is no definite answer to that in documentation and there is no "changelog". It is impossible to tell until somebody does a comparison between Gen 1 and Gen 2 parts.

There were changes to manufacturing and dealer documentation released after GM got samples of failed transmissions from the field, so should not be worse.

Things that are known to be better in Gen 2 (contributions welcome):

-

Valve body replacements are available separately for 2016+ CVT7s which decreases the repair cost in case the valves (known as solenoids) or valve body fluid channels go bad.

-

Based on a cursory look at Gen 2 disassembly video (https://www.youtube.com/watch?v=70n7Xxu5g-s), the Low Brake hub design is improved. https://youtu.be/CDWVwDcb8zI?t=858 states that driving aggressively with a weak hub may result in shearing and loss of forward motion, and Gen 2 has the stronger part.

Q&A

- Q: Should I switch to neutral when coasting?

-

I would not recommend doing that for safety reasons. While this most likely won’t damage the transmission, you lose the ability to accelerate out of the harm’s way if needed.

-

Q: Can I switch directions (forward/reverse) before a full stop?

-

You should not. This will put added stress on the belt that will cause it to slip. Transmission will, however, switch to neutral if you are travelling forward and switch to reverse without stopping. You do not want the belt to slip, so come to a full stop before changing direction.

-

Q: Where can I get the true information about the service procedures?

- I use ALLData DIY (https://alldatadiy.com), though other providers exist. The most official source is ACDelco TDS (https://www.acdelcotds.com/), which costs a lot, but a single subscription grants access to documentation to all the GM vehicles for the last decade and more.

Closing notes

In general, if you don’t experience any shudder, and sudden loss of power, change your transmission fluid regularly. Even though the official “severe” interval is 45,000 miles, I started experiencing shudder at around 25,000 miles. After changing the fluid, the shudder disappeared within the first 5 miles. It stopped hesitating on acceleration, but it is slow to accelerate like it was on its first day, as designed.

Having researched all the items above I decided to minimize harsh acceleration events and more often coast to stops. At least this way I’ll know I am not making this transmission do more work than needed.

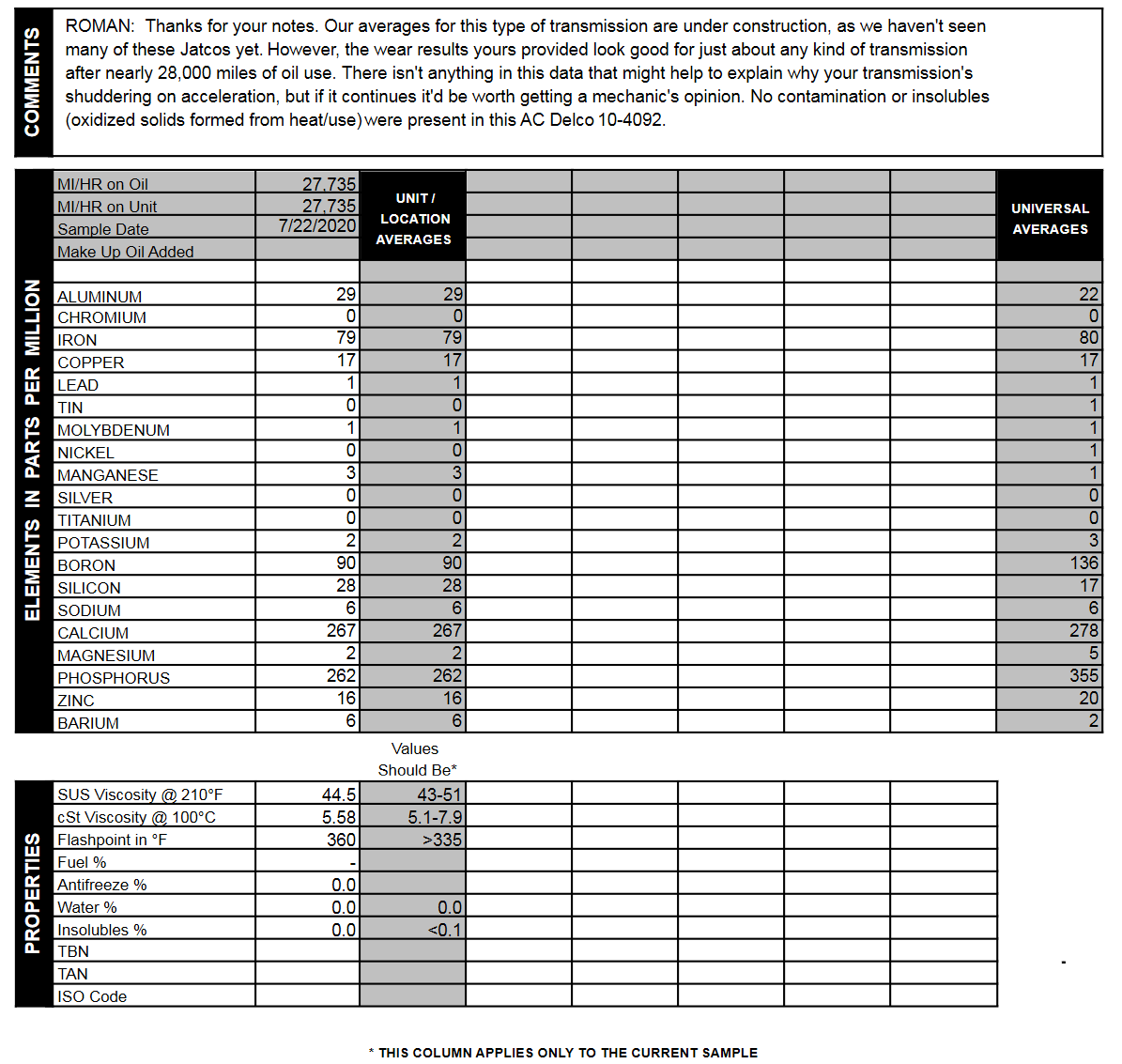

Having changed my CVT Fluid, I've sent a sample to https://www.blackstone-labs.net and received a report suggesting that even though the fluid smelled burnt, it did not had insolubles (oxidized solids formed from heat/use): r/chevyspark - Inside the Spark: Continuously Variable Transmission: It's All About the Fluid

As a mostly "armchair" mechanic I take pride in providing the most accurate and comprehensive information about the subjects I am covering, however, given the lack of hands-on experience, errors are inevitable. Let me know if you notice any inaccuracies.

Sources

-

https://gearsmagazine.com/magazine/the-mystery-behind-nissanjatco-cvt-pulleys/

-

https://www.youtube.com/watch?v=NxTvhJdXjX4 - Disassembly of a Gen 1 CVT7 unit (Korean)

-

https://www.youtube.com/watch?v=70n7Xxu5g-s - Disassembly of a Gen 2 CVT7 unit with snapped belt, presumably failed due to CVT fluid leak into radiator (Korean)

-

https://www.youtube.com/watch?v=yPGI_Jlb-h8 - Reassembly of a CVT7 unit

-

https://www.transmissiondigest.com/the-new-jatco-jf015e-when-is-a-cvt-not-a-cvt/

-

https://gmpowertrain.nexpart.com/ - powertrain pictures and specs

-

https://namu.wiki/w/%EC%89%90%EB%B3%B4%EB%A0%88%20%EC%8A%A4%ED%8C%8C%ED%81%AC (Korean)

-

https://www.nissan-global.com/EN/TECHNOLOGY/OVERVIEW/xtronic_cvt_auxiliary_transmission.html

-

Information about 2014-2015 Sparks from ACDelco TDS.

-

https://www.reddit.com/r/chevyspark/comments/fhy82s/transmission_recall/ - u/thumpah_da_wolf's post about the 2014-2015 campaign replacement results.

-

https://www.reddit.com/r/chevyspark/comments/fb7yuf/gm_techlink_article_about_sparks_jatco_cvt/ - my initial post asking for comments.

-

https://youtu.be/CDWVwDcb8zI?t=858 - Disassembly of a Suzuki CVT7 unit (Russian), comparison of two forward Low Brake hubs.

-

https://www.carscoops.com/2016/03/opel-adds-affordable-easytronic-30/ - Automated Manual Transmission.

Revision history

2020-07-29: Initial version.

2020-07-30: Formatting, add info on why deteriorated fluid slips, remove wording comparing to manual transmission, add u/glassgypsy campaign letter link.

2020-07-31: Add why fluid pump would fail, adjust wording, move campaign letter photo link to the body (mobile reddit displays first link as the hero image). Add sources.

2020-08-02: Add reference to CVT disassembly video from Gen 2 vehicle, mention sun gear fault from transmissiondigest. Add video of Suzuki CVT7 disassembly. Mention that cooling loop within a radiator leak may cause CVT failure.

2020-08-02.2: Correct that the Low Brake Hub is reinforced on Gen 2 after looking at the stop frames of https://www.youtube.com/watch?v=NxTvhJdXjX4, https://www.youtube.com/watch?v=70n7Xxu5g-s and using the comparison at https://youtu.be/CDWVwDcb8zI?t=858.

2020-08-02.3: Add info on AMT in Opel Karl, correct typos, state the pressure transfer is the main purpose, add blackstone labs report.

2020-08-04: Add info on belt/pulley wear as the (apparently) main failure point. Relocate Footnote into Closing notes.